Korean scientists develop new production technology for nanowire, key to developing cutting-edge electrical, electronic components

성수 최 2009-05-21 View. 5,480KAIST Professor Kim Sang-wook's team uses molecular assembly nano technology.

A new chapter has opened in the production of nanowire, widely considered one of the top 10 technologies that will change the world.

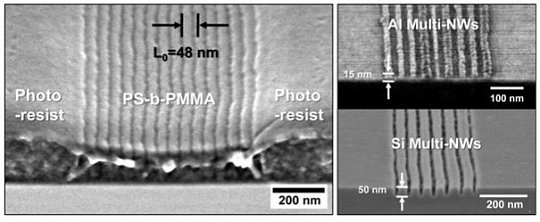

A team of researchers led by Prof. Kim Sang-wook at the new materials department of KAIST (President Suh Nam-pyo) said on May 11 that it had developed a new method for arranging polymers that independently form nanopatterns on a large surface, and had also used the method to develop a technique that allows for the easy and convenient production of nanowire at a specific location as required.

Kim's team composed a nanostructure that is self-arranged in various forms by filling polymers that formed nanopatterns on their own in micro patterns. The researchers then demonstrated that they could create an aluminum nanowire and silicon semiconductor nanowire on a large surface by using the nanostructure as a template. Moreover, the team successfully measured the electrical characteristics of the aluminum nanowire that was created thorough this process.

The result of the study was published in the May 7th online edition of Nano Letters, a world renowned scientific journal in nanotechnology. Steps are now underway for the registration of patents for related technologies.

(Photo)Sectional diagram of PS-b-PMMA block polymers in a platy structure which are arranged between photo register patterns, and of aluminum nanowire and silicon nanowire that were created using the structure as a template.

One of 10 technologies that will change the future.

Nanowire is considered one of 10 technologies that will change the face of the future, and is the most critical factor for the development of cutting-edge electrical and electronic components, including transistors, memories, and sensors for chemical detection. However, the production of a nano-size template using conventional technology has generally been highly costly and time-consuming, creating a need for a new production technology.

A researcher with the KAIST team said, "The new technology is expected to be widely used in the production of biosensors and multi-layer nanotransistors."

?

?

ScienceTimes

Kim Chung-han

chkim at kofac.or.kr

[May 21, 2009]

- - - - - - -

Source - ScienceTimes

Delete Article!

Delete Article!