KIMS secures technology for highly porous, sturdier ceramic

성수 최 2009-07-22 View. 15,596Efforts kick off to commercialize core technology for microcellular, porous ceramic?

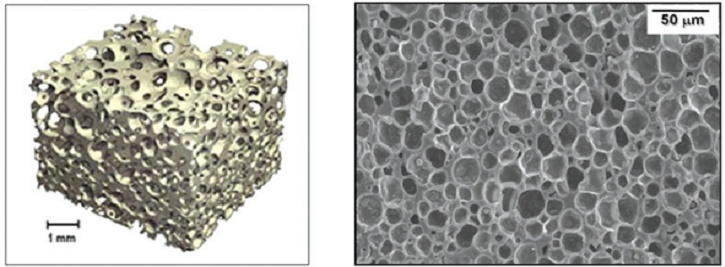

(Photo) Efforts are underway to commercialize a state-of-the-art core technology that allows for the creation of invisible holes in ceramic materials but minimizes the deterioration of the mechanical functions of such materials.

A team led by Dr. Song In-hyuk of the engineering ceramics research group at the Korea Institute of Materials Science (Director Cho Kyung-mok) said on July 13 that, working with a research team led by Dr. Kim Young-wook at the University of Seoul, it jointly developed a core technology for microcellular, porous ceramic, a material for which pore control is of utmost importance.

Song's team is jointly conducting research with Youngjin Ceramics (CEO Bae Ji-soo) and Namkang Ceramics (CEO Yoon Dal-woong) to commercialize the technology and transfer related technologies. Notably, Youngjin Ceramics successfully produced a setter (a structure that maintains its electrical characteristics when forming ceramic products, including electronic parts and porcelain) comprising diverse formations based on the core technology.

Dr. Song said, "By applying microcellular, porous ceramic technology, and thus reducing the weight of ceramics through the presence of numerous pores, we can produce components that can enhance efficiency in heat treatment when forming, and that are consistent in composition thanks to convenient degreasing on the contact surface at the bottom resulting from enhanced porousness."

With the adoption of the technology, the porous Zirconia setter is expected to cut materials costs of a product by 40 percent and production costs by 20 percent, allowing producers to rake in 1.5 billion won in annual sales.

Dr. Song said, "We have conducted research since 2001, and initially focused on the acquisition of core technology, including the development of new processes," adding, "Through proactive research collaboration with companies, we aim to commercialize in the short-term strategic items, including vacuum chuck materials that can be applied to semiconductor equipment and LCD equipment, which require a high level of porousness, and a light tile material that allows for humidity control as an eco-friendly construction material."

Additionally, Dr. Song's team and Youngjin Ceramics are expanding the applicability of the technology by producing porous Zirconia setters and a brush for polishing printed circuit boards. As such, experts predict the technology will highly likely find applications in other fields in the future.

Dr. Song said, "The microcellular, porous ceramics technology will emerge as a technology for creating core materials that overcome technological barriers in the areas of the environment, precision machinery, automobiles, construction materials, medical components and fuel cell projects."

Amid increasing international concern for environmental matters, porous materials are catching on around the world in the fields of desulphurization, denitrification, and filters aimed at curbing environmental pollution. As such, the utility and value of microcellular ceramics that boast functional superiority over conventional porous materials will likely increase further.

The applicability of the technology is also expected to expand to include semiconductors, heat-resistant tiles for space shuttles, high pressure ramps, and artificial bones and joints.

Lim Eun-hee,

redant645 at hellodd.com

[July 21, 2009]

- - - - - - -

Source - HelloDD.com

Delete Article!

Delete Article!