Scientists create 'artificial insect eye' to allow for wider, brighter view

성수 최 2009-10-27 View. 18,035Scientists create 'artificial insect eye' to allow for wider, brighter view.

KAIST Prof. Yang Seung-man develops micro-sized insect eye structure.

To use photonic dome as sensor for high-precision, micro-volume material in new drug development process.

(Photo) Prof. Yang Seung-man.

Insects' eyes have a wider perspective and are better at gathering light than humans' eyes, thus allowing insects to sense minute changes in their environment. For this reason, world-leading research groups have been working to develop artificial insect eyes for more than 20 years now.

A Korean research team has successfully developed a micro-sized artificial insect eye. The National Creative Research Initiative Center for Integrated Optofluidic Systems led by Prof. Yang Seung-man of the Department of Chemical and Biomolecular Engineering at KAIST (President Suh Nam-pyo) has produced an artificial insect eye for the first time in the world using a handy, self-assembly method, and has secured a competitive edge globally.

If scientists can arrange many eyes in one given space and increase the density of the array, the eyes can process more data to a corresponding extent. The micro-sized artificial insect eye(40 micrometers) developed by Prof. Yang's team is smaller than not only the conventional microlens(several millimeters) but also a hair strain(100 micrometers), and allows scientists to sense materials in a far more precise fashion. Develops world's smallest artificial insect eye using nanotechnology.

Unlike mammals, insects have compound eyes comprising tens of thousands of ocellus. Individual ocelli that tightly fill the surface of dome-shaped compound eyes are transparent convex lenses, which gather light and send data to the brain, which in turn senses an object by reintegrating data transferred from tens of thousands of ocellus.

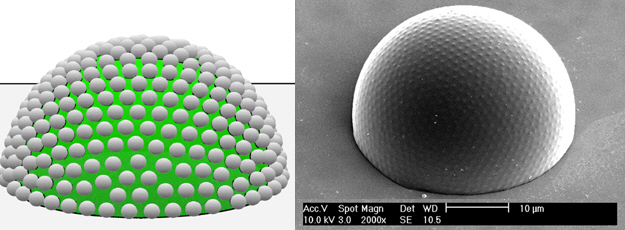

(Photo) Compound eye structure of dragonfly (left), and fly (right). Individual ocelli are arranged tightly in the hexagonal close-packing structure, covering the dome-shaped compound eye.

Many scientists have tried to generate artificial structures in nature that can process light data, including insect eyes, offal, and butterfly wings. Recently, some scientists reported the development of an artificial insect eye sized at several millimeters, or the actual size of insect eyes, but most attempts have failed to develop a practical structure.

Prof. Yang's team developed a method that allows for the production of a micro-sized artificial compound eye measuring several one-hundredths the size of a real insect eye. Notably, the team easily developed an artificial insect eye structure that is consistent in size and shape by using the auto-assembly principle of nano-marbles, and thus reduced the duration of its production process from dozens of hours to minutes.

The research team dispersed glass marbles(individual eye lenses) measuring hundreds of nanometers in size in water, and injected consistently sized oil bubbles measuring dozens of micrometers in size. Under these circumstances, if the balance of surface chemical energy is maintained between water, oil and glass marbles, the glass marbles move to an area sandwiched between water and oil bubbles.

Subsequently, if the compound of water, glass and oil bubbles is spread on a circuit board, the oil bubbles are transformed into a hemispheric dome, while glass marble lenses are tightly arranged automatically to form a hexagonal close-packing structure. The oil bubbles are then exposed to ultraviolet rays to consolidate the structure, generating an artificial insect eye.

Prof. Yang said, "The dome-structured insect eye, which is installed with thousands of micro-sized lenses, has a wider perspective and stronger capacity to gather light than human eyes."

(Photo) A diagram (left) and an SEM image (right) of an artificial insect eye structure that has been created using nano-assembly technology: ocelli (microlenses) measuring one micrometer each are arrayed at regular intervals on the hemispheric dome, which measures 40 micrometers in diameter.

Technology to be used as high-precision sensor device. The newly developed artificial insect eye can be applied to diverse fields that require ultra-sensitive sensor devices, since it is capable of recognizing minute changes in its environment.

Particularly, if adopted to the 'Lab on a Chip', a 'laboratory' on the physical scale of a semiconductor chip that can process an ultra-small amount of experimental reagents - a device that has recently been used in the commercialization of biotechnology processes, including new drug development - the micro-sized new artificial insect eye can be used as a high-precision sensor device.

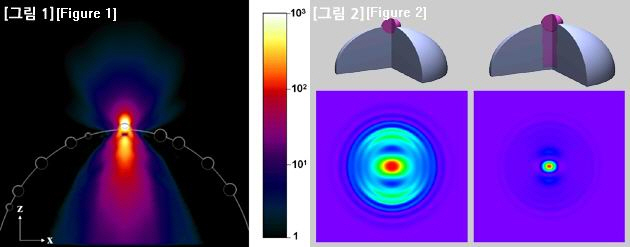

Figure 1: Transfer of light data without data loss through ocellus lenses.

Figure 2: The transferred light is gathered at the bottom of the dome due to the light-gathering effect of the dome structure.

Yang's study was published as the cover paper of the October issue of "Advanced Materials", an international scientific journal. It was also chosen as an "Advances in advance" article of the journal, as it was recognized for contributing to realizing the practical application of the artificial insect eye structure.

Additionally, noting the importance and applicability of Yang's study, Nature Photonics highlighted the study with the title "Micropatterning-Photonic domes" in the "News and Views" section of its October issue.

Prof. Yang's team has been conducting the study with the support of the Creative Research Initiative Program sponsored by the Ministry of Education, Science and Technology since 2006.

?

Jeong Yoon-ha

yhjeong at hellodd.com

Source - HelloDD.com

Delete Article!

Delete Article!