POSTECH scientists develop eco-friendly, terabyte-class data storage technology

성수 최 2009-09-25 View. 15,496POSTECH scientists develop eco-friendly, terabyte-class data storage technology

Study published September 14 in online issue of Nature Nanotechnology.

(Photo) Prof. Kim Jin-kon, and Jo A-ra, a doctoral program student at POSTECH.

Korean scientists have developed a new technology that is capable of storing 1.03 terabyte, a volume equivalent to 1,250 movie titles, per 2.54 square centimeters, roughly the size of a fingernail.

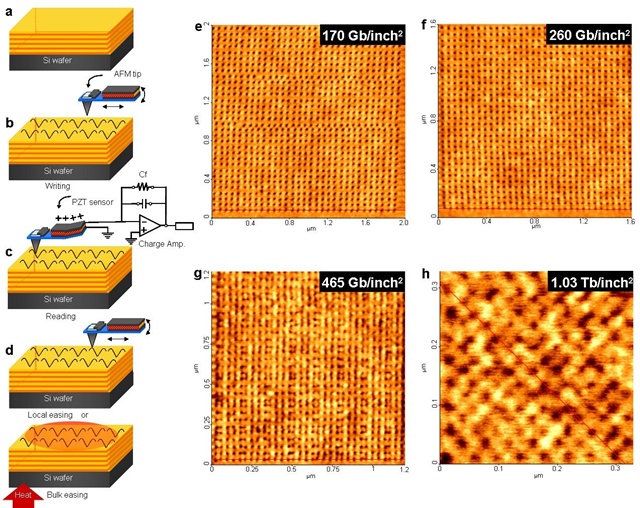

A research team led by Professor Kim Jin-kon at Pohang University of Science and Technology (POSTECH) said on September 14 that it developed a technology that allows for the production of a nanopattern that can store ultrahigh density data at terabyte levels on a polystyrene-block-poly (n-pentyl methacrylate), or a copolymer film, based on pressure at room temperature, by using a technology that stores data by a process in which the Atomic Force Microscope probe tip is made to come into mechanical contact with a copolymer surface.

Unlike conventional technology that requires the heating of the probe to up to the 350 degree Celsius-level to produce such storage, the new technology allows for the generation of a pattern at room temperature, which drastically reduces energy consumption due to high temperature formation, and thus constitutes an eco-friendly technology, an advantage that is drawing keen attention.

U.S. technology giant IBM, which is striving to develop next-generation terabyte-class information storage media, adopts research technology using a device that heats up the ATM tip to up to 350 degrees Celsius to induce plasticity in copolymer film during the string of procedures for data storage.

However, IBM's method renders it difficult to produce a tip that can be used at high temperatures, and exhibits heat conductivity of only 0.3% or less through the copolymer film. As a result, this method is low in efficiency and consumes a large volume of energy, which is required for controlling temperatures.

In order to overcome such shortfalls, Kim's team developed a polystyrene-block-poly on its own. The material will ultimately allow for the development of ultrahigh-density data storage media at room temperature using its pressure plasticity.

Kim said, "We have developed a technology that allows us to easily produce nanopatterns by using a copolymer block that can generate a nano structure at room temperature merely with pressure." adding, "The study has laid the groundwork for the development of technology for ultrahigh-density data storage media, which global enterprises are scrambling to develop."

Meanwhile, the study, which was conducted by Prof. Kim and doctoral student Jo A-ra jointly with LG Electronics, was published on September 14 in the online edition of Nature Nanotechnology, a world renowned scientific journal in the nanotechnology field.

(Photo) Artist rendition and Atomic Force Microscope image of the production process of the ultrahigh density nanopattern. Artist renditions (a-d) and Atomic Force Microscope image (3-h) of production process of ultrahigh density nanopattern for application as data storage media. Process of writing (b), reading (c), and erasing (d) patterns using the AFM probe tip at room temperature after creating polystyrene-block-poly (n-pentyl methacrylate), or PS-b-PnPMA, on Silicon wafer.

?

Lim Eun-hee

redant645 at hellodd.com

[September 25, 2009]

- - - - - - -

Source - HelloDD.com

Delete Article!

Delete Article!