Carbon Nanotube Thread Korean Researchers Developed

KISTI PR 2011-10-04 View. 9,273

Korean researchers have developed a production technology for 'carbon nanotube thread,' a high-tech material.

The Ministry of Education, Science and Technology(Minister Lee Ju-ho) said on February 16 that a research team led by Prof. Nam Seung-hoon of the Center for Nanoscale Mechatronics and Manufacturing under the 21st Century Frontier Research and Development Project had succeeded in developing carbon nanotube thread. The study was published as the cover paper in the January 1, 2011 issue of Carbon, an international science journal.

Seek to industrialize new material into functional composite materials, including those for bulletproof vests, aerospace components

Carbon nanotube thread, which is less than 1 micrometer(one 100th of a hair strand) thick, is comprised as bundles of multiple strands of successively integrated carbon nanotube.

Carbon nanotube thread is a material which is less than 1 micrometer thick. Since it boasts high elasticity and strength(some 100 times that of steel), it can be applied in diverse fields.

Dr. Nam's research team cultivated carbon nanotube vertically on a silicon board, formed bundles of multiple strands of carbon nanotube from it, and then reeled the substance into the form of thread to create carbon nanotube thread.

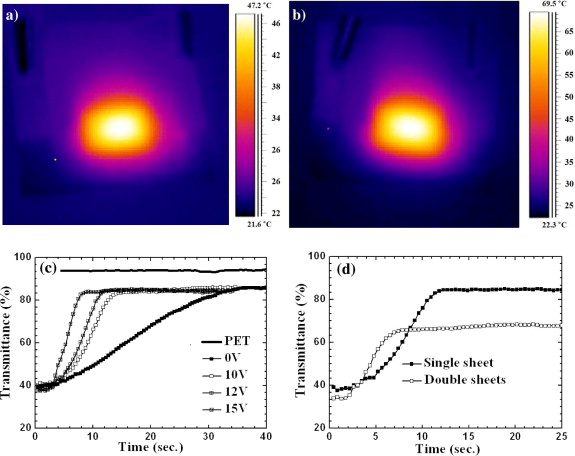

By applying voltage, the research team also succeeded in photographing the real-time change in shape that occurs on the tip of the carbon nanotube thread when electrons are emitted.

The technology allows for the reeling of multiple strands of carbon nanotube thread at once, or the easy coating of polymer substances on carbon nanotube thread. It also allows the material to be produced in sheet type as well as in thread form, thus making it possible to produce carbon nanotube film.

Carbon nanotube is flexible and highly conductive, and can thus be used as a material for touch screens. By taking advantage of its characteristic of emitting heat on the surface when a current is applied, the material can also be used in heaters to prevent fogging on automobile glass.

Kim Chung-han

chkim at kofac.or.kr

[February 23, 2011]

- - - - - - -

Source - ScienceTimes

Delete Article!

Delete Article!